FORGED TYPE

uniontech is contribute to the development of human culture

PRESSURE RATINGS

Pressure Ratings

These fittings shall be designated as pressure class 2000, 3000, and 6000 fittings for threading and presuure class 3000, 6000, and 9000 for socket-welding. This designation identifies the fittings with their ratings as shown as follow, ,Table 1

TABLE 1: Correlation of Fittings Class With Schedule Number of Wall Designation of Pipe for Calculation of Ratings

| PREESURE CLASS DESIGNATION OF FITTING |

TYPE OF FITTING | PIPE USED FOR RATING BASIC | |

|---|---|---|---|

| SCHEDULE NO. | WALL DESIGNATION | ||

| 2000 lb | Threaded | 80 | X - S |

| 3000 lb | Threaded | 160 | - |

| 6000 lb | Threaded | - | XX - S |

| 3000 lb | Socket-Welding | 80 | X - S |

| 6000 lb | Socket-Welding | 160 | - |

| 9000 lb | Socket-Welding | XX - S | |

This table is not intended to restrict the use of pipe of thinner of thicker wall with fittings.

Pipe actually used my be thicker in nominal wall than that shown in Table 1.

When tinner pipe is used it's strength may govern the rating.

When thicker pipe is used (e.g., for mechanical strength) the strength of the fitting governs the ratings.

TABLE 2: Nominal wall thickness of Schedule 160 and Double Extra Strong Pipe

| NPS. | SCHEDULE 160 | XX-S | ||

|---|---|---|---|---|

| in | mm | in | mm | |

| 1/8 | 0.124 | 3.15 | 0.190 | 4.83 |

| 1/4 | 0.145 | 3.68 | 0.230 | 6.05 |

| 3/8 | 0.158 | 4.01 | 0.252 | 6.40 |

TABLE 3: Pressure / Temperature Patings

Non-shock Working Presuure in Pounds per Square Incd

| 2000lb THREADED FITTINGS | |||||

|---|---|---|---|---|---|

| Service Temperature Degree °F |

Carbon steel | F304 | F316 | F22 | F5 |

| 100 | 2000 | 1715 | 2000 | 2000 | 2000 |

| 150 | 1970 | 1615 | 1970 | 1970 | 1970 |

| 200 | 1940 | 1520 | 1940 | 1940 | 1940 |

| 250 | 1915 | 1445 | 1915 | 1915 | 1915 |

| 300 | 1975 | 1370 | 1896 | 1895 | 1895 |

| 350 | 1875 | 1310 | 1875 | 1875 | 1875 |

| 400 | 1850 | 1254 | 1850 | 1850 | 1850 |

| 450 | 1810 | 1195 | 1810 | 1710 | 1810 |

| 500 | 1735 | 1140 | 1735 | 1635 | 1735 |

| 550 | 1640 | 1100 | 1640 | 1540 | 1640 |

| 600 | 1540 | 1060 | 1540 | 1440 | 1540 |

| 650 | 1430 | 1020 | 1430 | 1330 | 1430 |

| 700 | 1305 | 985 | 1370 | 1240 | 1340 |

| 750 | 1180 | 950 | 1305 | 1145 | 1245 |

| 800 | 1015 | 915 | 1240 | 1055 | 1155 |

| 850 | 830 | 880 | 1180 | 1060 | 1060 |

| 900 | 615 | 860 | 1115 | 970 | 970 |

| 950 | 425 | 845 | 1055 | 880 | 880 |

| 1000 | 235 | 830 | 990 | 740 | 695 |

| 3000lb THREADED FITTINGS | |||||

|---|---|---|---|---|---|

| Service Temperature Degree °F |

Carbon steel | F304 | F316 | F22 | F5 |

| 100 | 3000 | 2570 | 3000 | 3000 | 3000 |

| 150 | 2950 | 2425 | 2950 | 2950 | 2950 |

| 200 | 2915 | 2280 | 2915 | 2915 | 2915 |

| 250 | 2875 | 2170 | 2975 | 2975 | 2975 |

| 300 | 2845 | 2055 | 2845 | 2845 | 2845 |

| 350 | 2810 | 1965 | 2812 | 2810 | 2810 |

| 400 | 2775 | 1870 | 2775 | 2775 | 2775 |

| 450 | 2715 | 1790 | 2715 | 2715 | 2715 |

| 500 | 2605 | 1715 | 2605 | 2605 | 2605 |

| 550 | 2460 | 1650 | 2460 | 2460 | 2460 |

| 600 | 2310 | 1590 | 2310 | 2310 | 2310 |

| 650 | 2150 | 1535 | 2150 | 2150 | 2150 |

| 700 | 1960 | 1480 | 2055 | 2010 | 2010 |

| 750 | 1775 | 1425 | 1960 | 1970 | 1870 |

| 800 | 1525 | 1370 | 1865 | 1735 | 1835 |

| 850 | 1250 | 1330 | 1770 | 1595 | 1595 |

| 900 | 952 | 1290 | 1675 | 1455 | 1455 |

| 950 | 640 | 1270 | 1580 | 1320 | 1320 |

| 1000 | 350 | 1250 | 1485 | 1115 | 1240 |

| 6000lb THREADED FITTINGS | |||||

|---|---|---|---|---|---|

| Service Temperature Degree °F |

Carbon steel | F304 | F316 | F22 | F5 |

| 100 | 6000 | 5145 | 6000 | 6000 | 6000 |

| 150 | 5915 | 4855 | 5915 | 5915 | 5919 |

| 200 | 5830 | 4565 | 5830 | 5830 | 5830 |

| 250 | 5750 | 4340 | 5750 | 5750 | 5750 |

| 300 | 5690 | 4155 | 5690 | 5690 | 5690 |

| 350 | 5625 | 3930 | 5690 | 5625 | 5625 |

| 400 | 5550 | 3745 | 5550 | 5550 | 5550 |

| 450 | 5430 | 3583 | 5430 | 5430 | 5430 |

| 500 | 5210 | 3410 | 5210 | 5210 | 5210 |

| 550 | 4925 | 3305 | 4925 | 4925 | 4925 |

| 600 | 5620 | 3180 | 4620 | 4620 | 4620 |

| 650 | 4300 | 3070 | 4300 | 4300 | 4300 |

| 700 | 3920 | 2960 | 4110 | 4110 | 4110 |

| 750 | 3550 | 2850 | 3920 | 3920 | 3920 |

| 800 | 3050 | 2745 | 3730 | 3730 | 3730 |

| 850 | 2500 | 2660 | 3540 | 3540 | 3540 |

| 900 | 1885 | 2580 | 3350 | 3350 | 3350 |

| 950 | 1295 | 2540 | 3165 | 3165 | 3165 |

| 1000 | 715 | 2500 | 2975 | 2975 | 2085 |

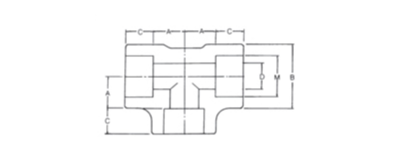

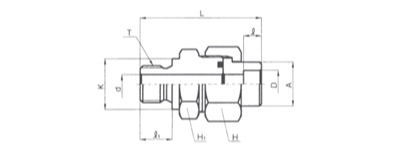

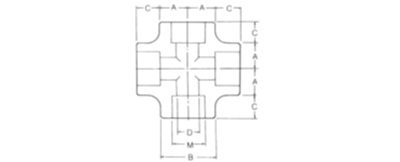

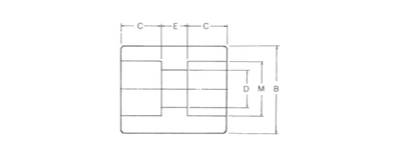

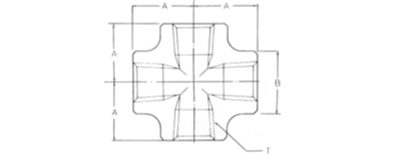

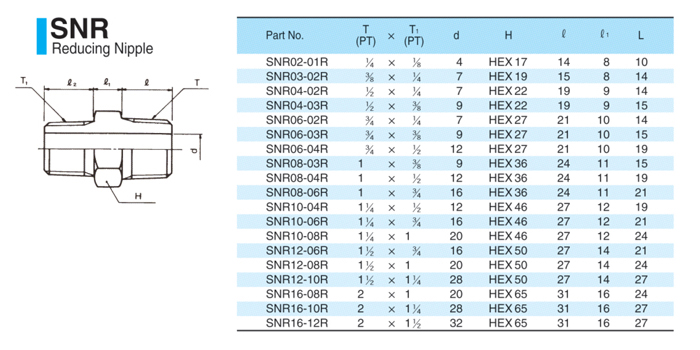

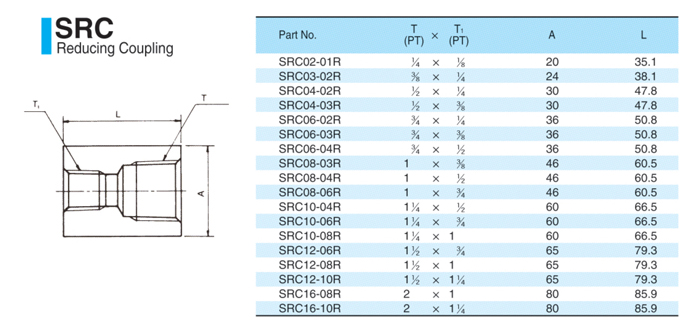

Size Identification

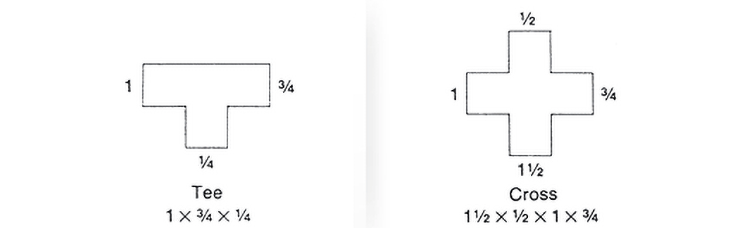

The size of a fitting is identified by nominal pipe size.

For reducting fittings, the size of the largest run opening is to be given first, follwed by the size of the opening opposite of the same run. The branch size of a Tee is givien last.

Where the case is a Cross, the largest side-outlet is thirdly given, then the oping opposite.

Threads

Unless otherwise specified in inquiry, all threaded fittings are supplied with NPT threads(ANSI B2.1 American Standard Taper Pipe Thread)for reference, other available threads are:

- ISO/R7, pipe threads for Gas List Tubes and Screwed Fittings where Pressure-tight Joints are mad on the Threads (BS 2.1 & JIS B0203PT Thread).

- API 5B, Line Pipe Threads

- KSB0222 Taper Pipe Theads.