DIN TYPE

make the invisible visible uniontech

GERAL INFORMATION FOR OUR BITE TYPE TUBE FITTINGS.

UNION TECH'S bite type tube fittings are precision machined, under strict quality control.

UNION TECH'S bite type tube fittings are the flareless tube fitting with visible bite.

This added safety feature makes UNION TECH'S bite type the preferred fitting for non-flared tube connections.

How Do they Works?

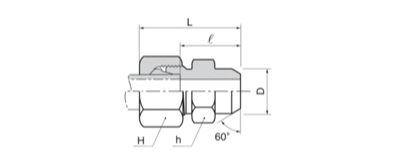

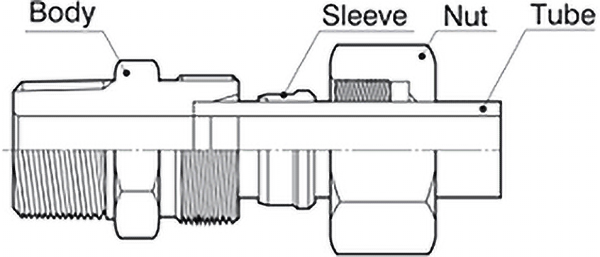

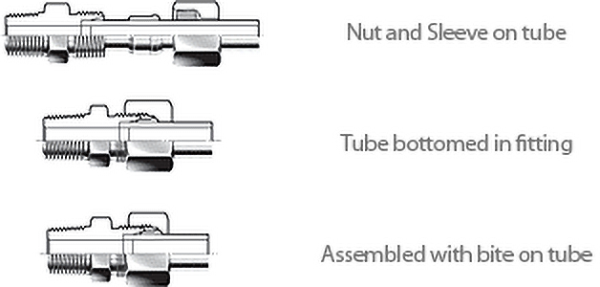

The bite type flareless hydraulic tube fitting was deisgned to work on medium to heavy wall tubing which was hard to flare and has three parts:

- body

- Sleeve

- nut(As shown in Fig-1)

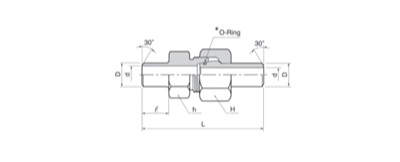

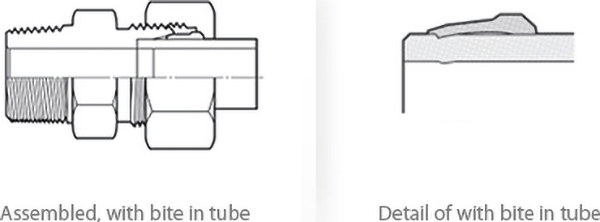

The sleeve is driven forward on the tube by the nut. As the sleeve moves forward it meets the seal seat angle of the body which causes the sleeve to cam inward into the tube. The Sleeve then bites into the tube causing a samall ridg of tube material to be pushed up in front of the biting edge of the sleeve. (As shwn in Fig-2&3)

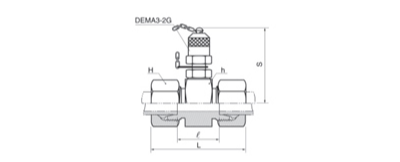

Fig-1

The make up of the fitting is critical in that the tube must be bottorned against the tube stop inthe body or presetting tool during make up. if it is not bottomed the tube will move forward with the sleeve and a bite will not be achieved Make sure the tube is bottomed.

A check is possible to see if the tube was bottorned during make up, To make this check look at the of the tube. into the tube and face. This impression will be caused by the tube stop which has a slight reverse angle rather than a flat face

Fig-2&3

Material Specfications

| PARTS | STEEL | STAINLESS STEEL | BRASS |

|---|---|---|---|

| Forged Body | S20C - S48C | SUS316 - SUS304 | C3771 |

| Bar stock Body | S20C - S48C | SU316 - SUS304 | C3604 |

| Cold Formed Nut | S10C - S20C | ||

| Bar Formed Nut | S20C - S48C | SUS316 -SUS304 | C3604 |

| Sleeve | S10C | SUS316 - SUS304 | C3604 |

Applicable Pressure Rating

Our standard specifications of fittings, which are shown in the catalog. Are as Blow

| FITTING SIZE(Applicable Tube O.D) | 4 ~ 15 | 16 ~ 22 | 25 ~ 28 | 30 ~ 38 | 40 ~ 45 |

|---|---|---|---|---|---|

| RATED PRESSURE ( kgf / ㎠ ) | 500 | 400 | 350 | 250 | 210 |

| RATED PRESSURE ( °C ) | 300 | ||||

The Rate Pressure for the fittings are determined based on the results servere repetitively conducted tests and the design calculation: precisely, the rated pressures are determined for each size of fitting while the safety factory of as much as 4 is taken in to account in the design.

Suitable Tubing Materlals

Common materal of tubing best suited for industrial service, and in accordance with variou Industry Standards and recommendations of tubing manufactures, include :

| STEEL |

Seamless, fully annealed, also welded and redrawn type suitable for bending. Maximum hardnss, Rockwell B72. |

|---|---|

| STAINLESS STEEL |

Seamless, fully annealed, also welded and redrawn, fully annealed suitable for bending. Maximum hardnss, Rockwell B90. |

| COPPER |

Seamless coils, soft or light annealed, Maximum hardnss, Rockwell F55 Straight lenghts. light drawn and general purpose. Maximum hardnss, of 60 on Rockwell 30T scale. |

Assemely Instructions

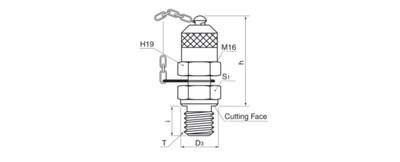

| CUTTING THE TUBE | Cut tube squarely and lightly de-burr the end internally and externally. |

|---|---|

| SLEEVE PLACEMENT | Slip nut and sleeve onto tubing. Be sure the long, straight end of sleeve point toward tube end. |

|

|

| LUBRICATIONS | Lightly lubricate threads on tool or body as well as the tail and lead end of the sleeve with a extreme friction lubricant. |

| PRE-STTING | Insert tube end into tool or fitting until it bottoms against the shoulder (to hold tube motionless during pre-setting operation) and screw nut down finger tiger. |

| FINAL SETTING | Wrench nut down 1-1/4 turns to pre-set the sleeve Reliable make up of all flareless tube fittings is dependent upon the sleeve traveling a prescribed distance into tapered fitting throat in order to bite into the tube and effect a posivive grip and seal. |

Reassemble For Final Instsllstion

Insert the tube into the fitting body and wrench the nut down easily until a sudden in crease in torque is evident. From this poiont turn the nut an additional 1/4 to 1/3 turn(1-2/2 to 2 wrench flats) to againsrping the sleeve into place to seal aginst the tubing and the fitting body.

Inspection Of Bite

All UJNION TECH'S bite type tube fittings must be disassembled and Inspected for proper make-up be fore final assmbly.

Detailed inspection procedures are outlined below and must be followed regardless of the method used to pre-set the sleeve to the tube.

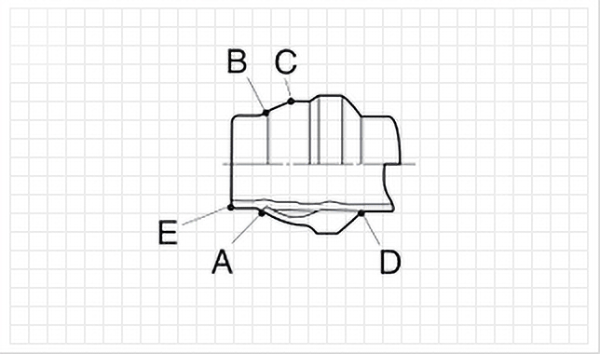

You Should Make Certain That

- A ridge of metal has been raised above the tube surfaces, to a hight of at least 50% of the hickness of the sleeve leading edge, completely around the tube(A)

- While the leading edge of the sleeve may be coined flat(B) there is a slight bow to the balance of the pilot section(C)

- The tail or back end of the sleeve is snug aginst the tube(D)

- There is slight indentaiton all around the end of the tube(E) that indicates the tube was bottomed in the tool or fitting during pre-setting(unless evidence of complete contact is visible the sleeve cannot be considered preoperly pre set).

- Avoid rotating the sleeve. Steel sleeve should not be capable of moving back snd forth along tube, beyond the bite area(stainless steel sleeve will move than steel because of it's spring back characteristics).

Trouble shooting

Problem with bite type hydraulic fittings are most often traced to faulty make up preocedures. Look for the following:

| TUBE NOT BOTTOMED | Avoid rotating the sleeve. Steel sleeve should not be capable of moving back snd forth along tube, beyond the bite area (stainless steel sleeve will move than steel because of it's spring back characteristics). |

|---|---|

| LACK OF BITE | Inspect for turned up ridge of material. A failure to achieve this ridge can be traced either to the fact that the nut was not tightened enough or that the tube was not bottomed against the stop which allowed the tube to travel forward with sleeve. |

| SLEEVE COCKED ON TUBE | The sleeve is cocked on the tube when the tube assembly is off axis with that of the body. Generally this condition is caused by faulty tube bending. All bent tube assemblies should drop into fitting body prior to make up. |

| NO BITE | If all of the above checks have been made and the sleeve stil shows no sign of biting the tube , it may be the the tube is too hard. |